We assure to deliver superior finish quality products with consistency at an economical price. Our product manufactured goes through various test procedures at every stage right from the material selection to slitting, pipe making, polishing, end product testing, packaging and warehousing. Timely reviewing and monitoring the production process at each s tage is s trictly adher ed in or der t o deliv er the pr oduct with utmos t qual ity

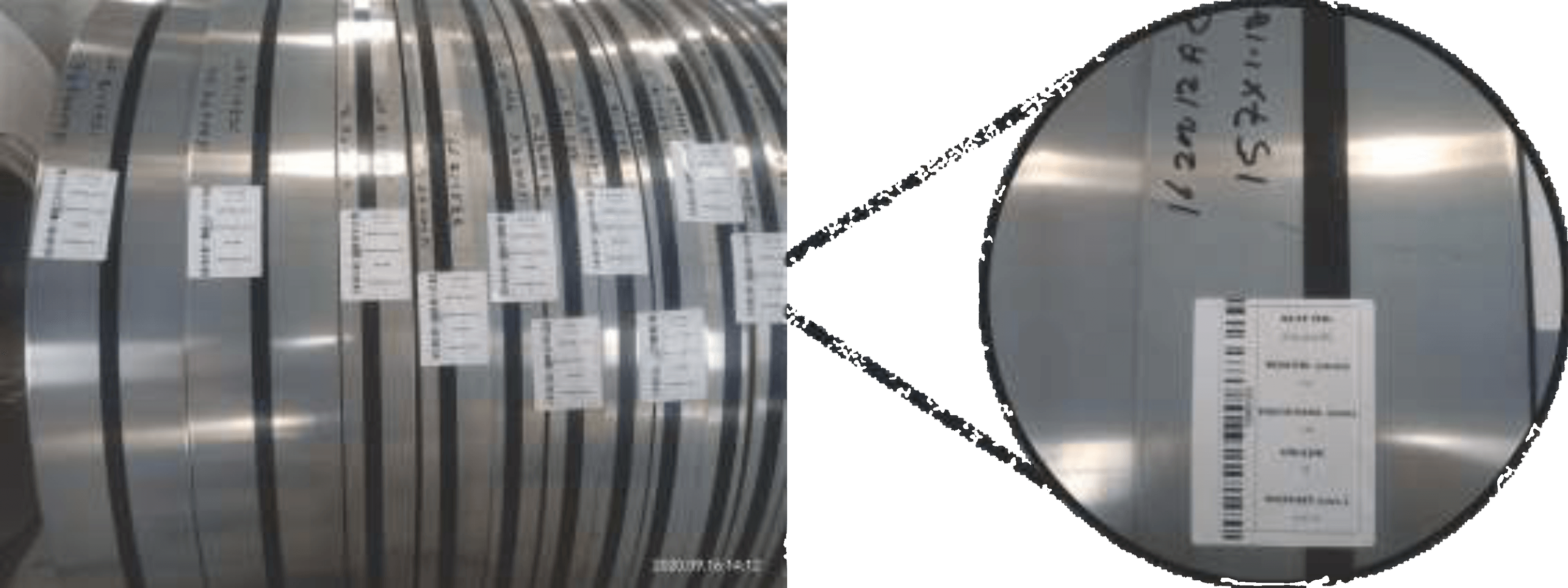

Barcoding of each Products

- Helps in identification of Grade, Thickness, Size, etc.

- Serves as a source of truth for any cross verification.

- Incentives, in-kind passed on to our esteemed dealers and the end users of the product

- Even the end customer can trace the origin and batch number incase of complaints, if any

Weight Chart

| WEIGHT CHART OF STAINLESS STEEL ROUND, RECTANGULAR AND SQUARE TUBES IN KG | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DAIMETER | WALL THICKNESS | |||||||||||

| SS 202 / JT GRADE | SS 304 GRADE | |||||||||||

| In Inch | In mm | 24 SWG (0.68 mm) |

22 SWG (0.78 mm) |

20 SWG (0.90 mm) |

18 SWG (1.15 mm) |

16 SWG (1.45 mm) |

22 SWG (0.78 mm) |

20 SWG (0.90 mm) |

18 SWG (1.20 mm) |

16 SWG (1.50 mm) |

||

| 1/2 | 12.70 | 1.24 | 1.41 | 1.61 | 2.01 | 2.47 | 1.41 | 1.61 | 2.09 | 2.55 | ||

| 5/8 | 15.88 | 1.57 | 1.78 | 2.04 | 2.57 | 3.17 | 1.78 | 2.04 | 2.67 | 3.27 | ||

| 3/4 | 19.05 | 1.89 | 2.16 | 2.48 | 3.12 | 3.87 | 2.16 | 2.48 | 3.25 | 3.99 | ||

| 7/8 | 22.23 | 2.22 | 2.54 | 2.91 | 3.67 | 4.57 | 2.54 | 2.91 | 3.82 | 4.71 | ||

| 1 | 25.40 | 2.55 | 2.91 | 3.34 | 4.23 | 5.26 | 2.91 | 3.34 | 4.40 | 5.43 | ||

| 1 1/4 | 31.75 | 3.20 | 3.66 | 4.21 | 5.33 | 6.66 | 3.66 | 4.21 | 5.56 | 6.88 | ||

| 1 1/4 x 18 ft | 38.10 | 3.48 | 3.98 | 4.57 | 5.81 | 7.26 | NM | NM | NM | NM | ||

| 1 1/2 | 38.10 | 3.86 | 4.41 | 5.07 | 6.44 | 8.05 | 4.41 | 5.07 | 6.71 | 8.32 | ||

| 2 | 50.80 | 5.16 | 5.91 | 6.81 | 8.65 | 10.84 | 5.91 | 6.81 | 9.02 | 11.21 | ||

| 2 1/2 | 63.50 | 6.47 | 7.41 | 8.54 | 10.86 | 13.63 | 7.41 | 8.54 | 11.33 | 14.09 | ||

| 3 | 76.20 | 7.78 | 8.91 | 10.27 | 13.08 | 16.42 | 8.91 | 10.27 | 13.64 | 16.98 | ||

| 1/2 x 1/2 | 12 x 12 | 1.57 | 1.78 | 1.78 | 2.57 | 3.17 | 1.78 | 2.04 | 2.67 | 3.27 | ||

| 5/8 x 5/8 | 15 x 15 | 1.89 | 2.16 | 2.04 | 3.12 | 3.87 | 2.16 | 2.48 | 3.25 | 3.99 | ||

| 3/4 x 3/4 | 20 x 20 | 2.55 | 2.91 | 2.48 | 4.23 | 5.26 | 2.91 | 3.34 | 4.40 | 5.43 | ||

| 1 x 1/2 | 26 x 13 | 2.55 | 2.91 | 3.34 | 4.23 | 5.26 | 2.91 | 3.34 | 4.40 | 5.43 | ||

| CAPSULE | 33 x 13 | 2.55 | 2.91 | 3.34 | 4.23 | 5.26 | 2.91 | 3.34 | 4.40 | 5.43 | ||

| 1 x 1 | 25 x 25 | 3.20 | 3.66 | 3.34 | 5.33 | 6.66 | 3.66 | 4.21 | 5.56 | 6.88 | ||

| 1 1/2 x 3/4 | 40 x 20 | 3.86 | 4.41 | 4.21 | 6.44 | 8.05 | 4.41 | 5.07 | 6.71 | 8.32 | ||

| 2 x 1/2 | 50 x 10 | 3.86 | 4.41 | 5.07 | 6.44 | 8.05 | 4.41 | 5.07 | 6.71 | 8.32 | ||

| 1 1/4 x 1 1/4 | 30 x 30 | 3.86 | 4.41 | 5.07 | 6.44 | 8.05 | 4.41 | 5.07 | 6.71 | 8.32 | ||

| 2 x 1 | 50 x 25 | 4.91 | 5.62 | 6.46 | 8.22 | 10.29 | 5.62 | 6.46 | 8.56 | 10.64 | ||

| 1 1/4 x 1 1/4 x 18 ft | 40 x 40 | 4.66 | 5.33 | 6.14 | 7.80 | 9.78 | NM | NM | NM | NM | ||

| 1 1/2 x 1 1/2 | 40 x 40 | 5.16 | 5.91 | 6.81 | 8.65 | 10.84 | 5.91 | 6.81 | 9.02 | 11.21 | ||

| 3 x 1 | 75 x 25 | 6.47 | 7.41 | 8.54 | 10.86 | 13.63 | 7.41 | 8.54 | 11.33 | 14.09 | ||

| 2 x 2 | 50 x 50 | 6.47 | 7.41 | 8.54 | 10.86 | 13.63 | 7.41 | 8.54 | 11.33 | 14.09 | ||

| 3 x 1 1/2 | 80 x 40 | 7.78 | 8.91 | 10.27 | 13.08 | 16.42 | 8.91 | 10.27 | 13.64 | 16.98 | ||

Mechanical Properties

| GRADE | Tensile Strength(MPA) (min) |

% Yield Strength MPA (min) |

% Elongation (min) |

Hardness HRB (max) |

|---|---|---|---|---|

| SS 304 | 485 | 170 | 40 | 92 |

| J4 | 650 | 325 | 40 | 100 |

| JSL-T | 650 | 325 | 40 | 100 |

| JSL-DD | 650 | 325 | 40 | 100 |

| JSL-SD | 650 | 325 | 40 | 100 |

| 409 | 380 | 170 | 20 | 88 |

| 409 L | 380 | 170 | 20 | 88 |

Chemical Composition

| GRADE | C % MAX | SI % MAX | MN % | CR. % | NI % | P % MAX | S % MAX | OTHER ELEMENTS % |

|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.07 | 0.75 | 2.00 MAX | 17.5 – 19.5 | 8 – 10 | 0.045 | 0.03 | – |

| SS 304 L | 0.03 | 0.75 | 2.00 MAX | 17.5 – 19.5 | 8 – 10 | 0.045 | 0.03 | – |

| J4 | 0.10 | 0.75 | 8.5 – 10.0 | 15 – 16 | 1-2 | 0.08 | 0.01 | Cu 1.5-2 |

| JSL-T | 0.10 | 0.75 | 9.0 – 10.0 | 14.5 – 16.5 | 0.25 – 0.35 | 0.1 | 0.01 | – |

| JSLU-DD | 0.15 | 0.75 | 9.7 – 10.7 | 15.1 – 16.0 | 0.45 – 0.60 | 0.1 | 0.03 | Cu 1.9 – 2.2 |

| JSLU-SD | 0.15 | 0.75 | 9.7 – 10.3 | 13.25–14.25 | 0.45 – 0.50 | 0.1 | 0.03 | Cu 1.25 – 1.75 |

| 409 | 0.03 | 1 | 1 | 10.5 – 11.7 | 0.5 | 0.04 | 0.02 | Ti = 6x(C+N) Min. 0.5 Max. |

| 409 L | 0.03 | 1 | 1 | 10.5 – 11.7 | 0.5 | 0.04 | 0.03 | Ti = 6x(C+N) Min. 0.75 Max. |